—

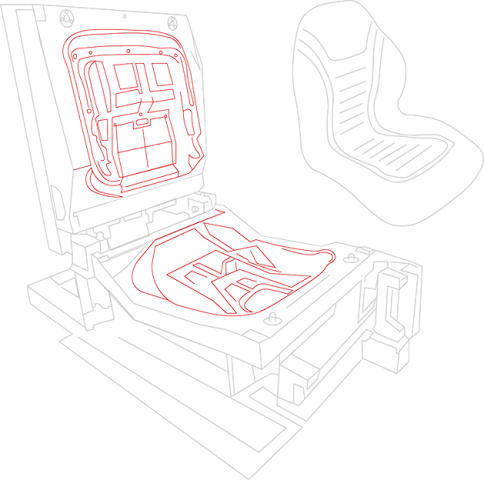

Intech Services, the exclusive distributor of Teflon* industrial coatings in the US & Canada, has announced a new product line that provide consistent release of polyurethane foam molding applications. The product’s superior performance in removing polyurethane foams from their molds makes it a superior alternative to traditional release agent sprays.

More information can be found at https://intechservices.com

Chemours’s breakthrough Teflon coating technology will provide many benefits to polyurethane foam manufacturers, such as improved production rates, reduce foam damage, reduced waste, reduced airborne release agent over spray, safer working conditions for employees, and greater compliance with environmental laws.

Polyurethane foam is a versatile material widely used in consumer and industrial markets. It is found in common consumer goods such as shoe soles, mattresses, furniture cushioning, adhesives, car parts, tires, and sportswear. In the construction industry, polyurethane is used in building insulation and architectural adhesives, among other uses.

Traditional release agent sprays require heavy use and provide only mediocre release of polyurethane foams from their molds. They also can cause maintenance and safety issues in the manufacturing facilities in which they are used. By contrast, Chemours’s new coating technology is a proprietary compound that allows long-term, consistent release while considerably reducing foam damage.

For example, the coating has also improved the performance of steel mixing blades used in polyurethane processing. Over time, foam residue builds up on the blades and can be removed only with a media blasting process, which reduces the blades’ service life. When applied to the blades, Chemours’s coating solution prevented the polyurethane build-up, thus extending the mixers’ production time, and made the blade-cleaning process more time- and cost-efficient.

More information about Teflon coating as a polyurethane build-up solution can be found at https://intechservices.com/content/Teflon-Cure-for-Uncured-Mixers-Polyurethane-Case-Study.pdf

The Chemours Company provides chemical solutions for a wide range of industries, including automotive, telecommunications, electronics, construction, and energy. Their business units focus on titanium technologies, thermal management, advanced performance materials like Teflon, and chemical solutions.

A spokesperson for Intech Services has said: “We are excited about the possibilities that lie ahead with our new coating solution. The polyurethane foam manufacturers that have used this technology have seen tremendous value in terms of consistent performance, reduced costs, and a safer, cleaner work environment.”

Interested parties can find more information at https://intechservices.com/teflon-coatings-in-the-polyurethane-industry

Release ID: 89049682